The construction industry has the highest percentage of electrical fatalities out of all industries. While electricity is a crucial component in a construction project’s success, it poses a risk of harmful shock, horrific burns, or fatal electrocution. These accidents can occur when workers come into contact with power lines, wiring, transformers, or other electrical machinery. Fortunately, there are steps that companies can take to minimize the dangers. The following are eight tips on how to improve electrical safety in the construction industry:

Provide protective equipment – Electrical safety starts at a personal level. All electrical work personnel or people working in an area with electrical materials should wear protective gear, such as insulated gloves and footwear. This provides basic safety if they come into contact with electrical equipment, whether accidentally or intentionally.

Train workers in handling electrical equipment – Electrical mishaps can occur when there is misuse or mishandling of electrical equipment. Workers should be trained on how to handle and operate the equipment safely. Conduct regular training to ensure your workers don’t become lax when they use the same equipment.

Use proper testing equipment – Proper testing equipment should be among the essential tools on a construction site. Voltage detectors, receptacle testers, and clamp meters are among the tools every worksite should have to enhance electrical safety and help prevent electrical accidents.

Install the right signage – Lack of awareness can lead to catastrophic electrical accidents. All electrical hazards should be marked to warn your workers of the dangers. The signs should have labels in language and illustrations that can be easily understood by a layman.

Conduct a risk assessment – Conduct a risk assessment survey of the worksite before operations begin. This will help identify hazards that can compromise electrical safety and allow you to come up with solutions accordingly. The assessment will also help your team develop a plan on how to layout electrical infrastructure with safety in mind. The plan should indicate where and how electrical equipment will be placed and how the wiring will be done.

Use circuit breakers and voltage regulators – Emergencies can occur in case of a power surge, short-circuit, or other electrical issues. That’s why it’s essential to have circuit breakers and voltage regulators to cut off power during such situations. The ability to regulate or shut down the power supply on time during a crisis can avert catastrophic damage.

Avoid wet conditions – Electrical equipment and infrastructures in the worksite should be shielded from coming into contact with water at all costs. This should be done during the planning process. When the equipment comes into contact with water, shut off the power supply immediately. It should be turned back on under a professional electrician’s recommendation.

Organize and insulate all exposed cables – A construction area should never have messy or uncovered power cables. When unorganized, the cables can contact each other, resulting in short-circuiting and possibly fire. If left uncovered, workers may accidentally touch them, leading to shock or electrocution. Cover all cables in a construction site with insulating material and organize the cables to enhance electrical safety.

The takeaway

While overall safety is a significant concern in the construction industry, electrical dangers can be contained if the right measures are implemented. The above tips can help construction firms to boost electrical safety in their operations. However, all the parties on a construction site must be diligent for maximum electrical safety.

Cyber Security

If one of your online accounts is hacked, especially a financial one, you could see your bank accounts drained and your identity is stolen. Digging yourself out of that hole could set you back for years and haunt you for more than a decade. Once someone has stolen your identity, they can apply for new credit lines and destroy your credit. Bill-collectors for liabilities they incurred can plague you for years.

There are usually two ways hackers will access your accounts:

- By duping you into clicking on a malicious link that will expose your password, or

- By guessing your password.

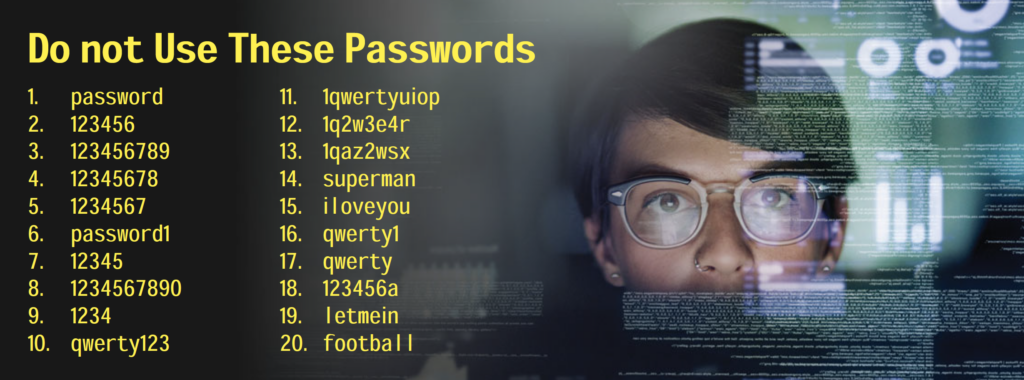

Sadly, many people make that easy for them by picking easy-to-hack passwords. If you want to protect your accounts and your finances, there are some passwords you simply should avoid. Safetydetective.com, an antivirus website, looked at more than 9 million stolen passwords in the U.S., resulting in this list of the most commonly hacked ones:

The takeaway

Safetydetective.com recommends that you require all of your staff to set passwords that are at least eight characters long.

Other best practices that you need to train your employees in include:

- Never reveal your passwords to others.

- Use different passwords for different accounts.

- Use multi-factor authentication (like a confirmation text to their phone).

- Use at least 16 characters whenever possible for passwords. • Use passwords that contain at least one punctuation mark or other special characters. For example: uSo38&_Xv3!0@

- Require them to change their passwords every 90 days.

Injury Prevention

Thousands of people are blinded each year from work-related eye injuries that could have been prevented with the proper selection and use of eye and face protection. Eye injuries alone cost more than $300 million per year in lost production time, medical expenses, and workers’ compensation.

OSHA requires employers to ensure the safety of all employees in the work environment.

Eye and face protection must be provided whenever necessary against chemical, environmental, radiological, or mechanical irritants, and hazards.

Eye and face protection is addressed in specific standards for the general industry, shipyard employment, longshoring, and the construction industry.

It is impossible to predict when and where an eye incident might occur, but it can happen literally in the blink of an eye, injuring or even blinding a worker who’s not wearing proper protection.

It’s an employer’s responsibility to identify the eye safety hazards at the workplace, and then provide workers with the best protection against them.

Along with training on how and when to use eye protection equipment, workers should learn about cleaning, storing, and replacing equipment.

In most cases, workplace eye injuries can be avoided if workers have been trained to know when and what eye protection equipment should be worn – and what to do in case of an eye injury.

Opposite are some common causes of eye injuries, with suggested first aid responses.

In all cases, professional medical attention should be sought as soon as possible after taking initial first aid measures.

Eye Injury Responses

Foreign particles

Go to the nearest eyewash station or water source and flush the eye until the object is rinsed out. Don’t rub the eye because the object can scratch or become embedded in the eye. If the object doesn’t rinse-free, bandage the eye loosely and seek medical attention.

Chemical splashes

Seconds count! These require immediate action. Go immediately to the nearest emergency shower or water source. Look directly into the stream of water, hold the eyes open with your fingers, and flush them for at least 15 minutes.

Light burns

Exposure to welding, laser, or other radiant light without appropriate eyewear does not cause immediate pain, but – four to 12 hours later – exposed eyes may begin to feel “gritty” and become sensitive to light. Redness or swelling may occur. Keep your eyes closed while waiting for medical attention.

Cuts

Don’t rub, press or wash cuts near the eye. This can cause further damage. Loosely bandage both eyes to stop any movement.

Embedded objects

Never try to remove objects embedded in your eye; this can cause further damage. Loosely bandage both eyes and get medical attention.

Bumps & blows

Apply a cold compress for 15 minutes to reduce pain.

Take Safety Precautions

The best solution for when workers are doing any work that could result in an eye injury is to wear proper eye protection. But accidents happen and your employees should know what to do if they suffer an eye injury.

Construction Industry

As the construction industry booms, contractors face evolving risks that, left unchecked, can leave their operation exposed to new liabilities. If you already operate a construction firm, you know that there is a labor shortage that has made it difficult to find experienced workers and that hiring entities are asking builders to take on more of the design function, as well. Your liability picture has also likely changed with the increasing use of wrap-ups and, if you’re using technology in your operation, you now have rising cyber-security risks, too.

Lack of qualified workers

The bottom fell out of the construction industry in the U.S. during the first few months of the COVID-19 pandemic, and many worksites were idled. Now that the industry has found its footing, it’s been dealing with a severe labor shortage. As construction firms struggle to find workers, the ones who are on the job are having to take on larger workloads, which can put them at risk of injury or making mistakes. Also, many contractors are having to take on younger, less seasoned laborers, who may lack the experience to identify and avoid hazards, which puts them and others at risk of injury. Those injuries in turn affect your workers’ comp premiums. A lack of workers coupled with inexperienced new ones on sites can also end up drawing out projects, forcing contractors to miss deadlines.

Professional liability risks

As more project owners want an all-in-one job with the lead contractor designing and building the project, contractors now face a new type of risk: professional liability. But the typical contractor’s insurance policy doesn’t provide protection for any design work you take on.

Courts have ruled that:

- Designers who perform “builder activities” lose the limitation of liability typically enjoyed by design professionals.

- Builders who perform “design activities” assume responsibility for design deficiencies.

Wrap-ups more prevalent

Many construction projects are now covered under one general liability policy to cover the work of the general contractor, as well as of all the subs. More lenders are requiring that liability is set up in one all-encompassing policy. A properly assembled general liability wrap-up should provide coverage not only during the construction period but also up to 10 years after the work is completed. These policies often reduce the cost of coverage.

More cyber-security risks

Like all industries, the construction sector has grown increasingly reliant on technology to get the job done. That exposes contractors to a variety of cyber risks, including keeping project designs, client records and employee records confidential. Many building contracts today include clauses requiring the contractor to be responsible for potential cyber breaches. Given the increasing popularity of practices such as “building information modeling,” “integrated project delivery,” and file-sharing between participants in a construction project, contractors may be at increased risk of liability in the event of a data breach.

This newsletter is not intended to provide legal advice, but rather a perspective on recent regulatory issues, trends, and standards affecting insurance, workplace safety, risk management, and employee benefits. Please consult your broker or legal counsel for further information on the topics covered herein.